Speeding up 3D microfabrication for bio-applications

We multiply fabrication speed in 3D microprinting using multiple beamlets to fabricate periodic structures simultaneously. Further, we perform first interdisciplinary studies with live cells. The findings of this interdisciplinary study are of relevance for i) industrial uptake of the nonlinear 3D microprinting technology and ii) for innovations in bioassays for cell biology research, tissue engineering, and potential drug development.

The results are the fruit of a collaboration between INL - International Iberian Nanotechnology Laboratory (Portugal) and

IMT Atlantique (France). Synergies were identified during meetings of delegations from IMT-A to INL that visited each other in preparation of a Memorandum of Understanding (MoU) between the institutions.

IMT-A’s team around Kevin Heggarty are experts in the design and fabrication of Diffractive Optical Elements (DOEs) that here were used by the Ultrafast Bio- and Nanophotonics group led by Jana Nieder at INL to develop a new parallelized way of microfabrication of microstructures for bioapplications.

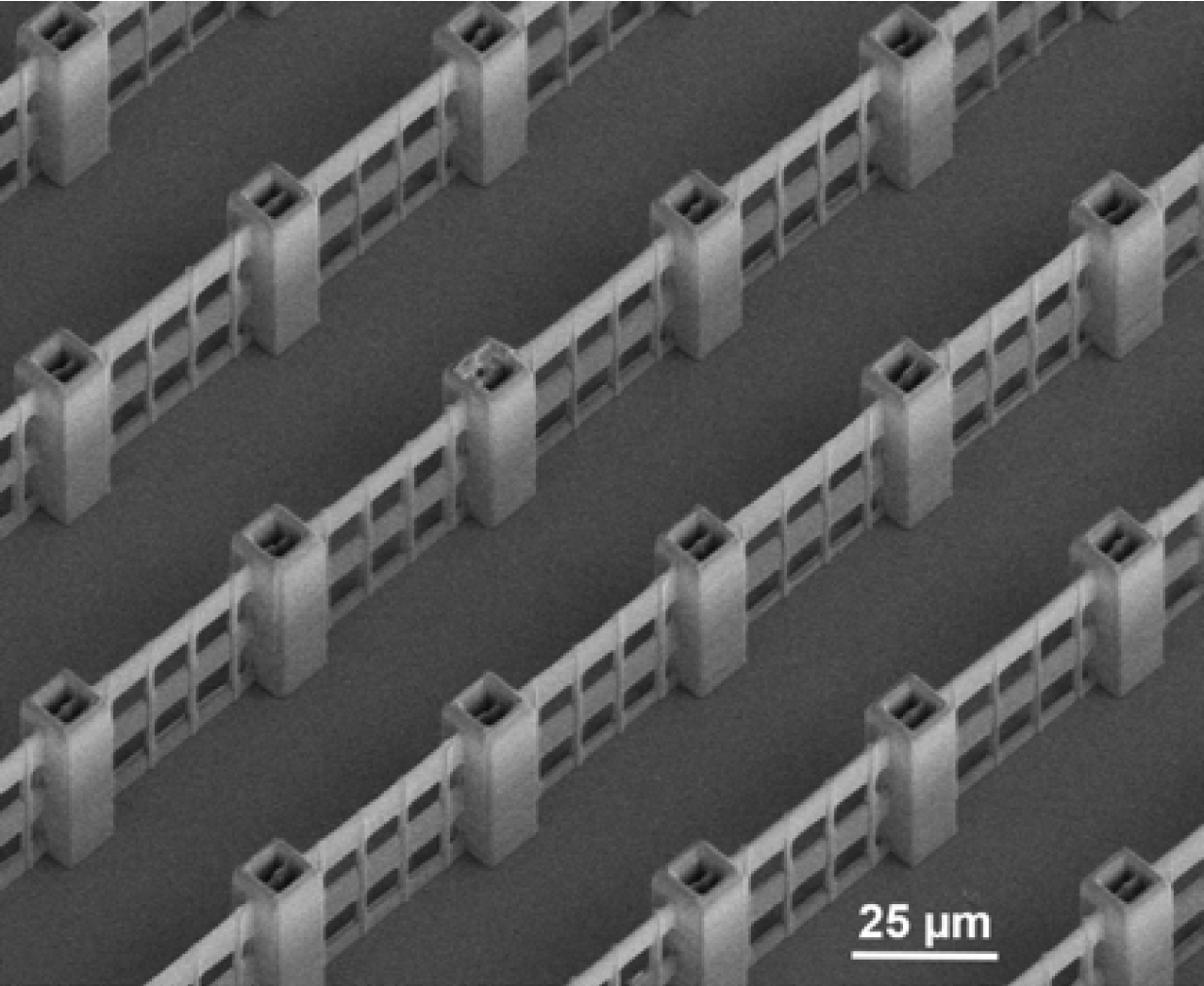

Christian Maibohm, the first author of the study, reveals: “Optimizing the nonlinear multibeam fabrication with excellent DOEs was a great experience. The laser-based fabrication process can be followed in real-time but only at low spatial resolution. Only hours or days after 3D microprinting - the moment of truth occurred when characterising the structures using high-resolution Scanning Electron Microscopy (SEM) imaging. Me and my colleague Jérôme Borme, who was performing the SEM imaging for the project, were fascinated about the high precision and repeatability on the sub-micro scale along with the rather large extended 3D microstructures, that nearly reach the millimetre scale.”

Oscar Silvestre, a Bioengineering Expert, provided the expertise needed to demonstrate the application of periodic structures in interaction with biological cells. The bio-compatibility and effect of the fabricated 3D microstructures on the growth and proliferation of HeLa-cancer cells were tested in the laboratory, using confocal microscopy. It was possible to observe enhanced cell-migration, attachment, and -proliferation for 3D incubated cells as compared to standard 2D reference substrates.

The polymer scaffolds function as an extracellular matrix providing the growth conditions for human cells based “synthetic” platforms that can be used for in vitro assays and replace some of today’s animal testing in the frame of pharmacologic research.

The method resembles macroscopic 3D printing, but instead of adding material bit-by-bit, a focused pulsed laser beam is traced through a photo-sensitive polymer. For true 3D features, we use the optical method of Two-Photon Polymerization (TPP). In every spot, where the laser resides long enough, the polymer material is hardened.

The multi-beam approach allows an upscaling of the otherwise cumbersome single beam fabrication technique, and thus facilitates its transition into a large volume fabrication methodology.

Jana Nieder mentions: ”I foresee considerable innovation potentials based on the upscaling strategy presented. High power lasers will enable an even larger parallelization. This will be the way forward for series production of complex 3D freeform architectures.”

Such 3D platforms will represent valuable tools to perform cell interaction experiments by providing more realistic biological models allowing for faster diagnostics and the development of new therapeutics.

This work is featured in the Springer Nature journal, “Scientific Reports”: C. Maibohm, O. F. Silvestre, J. Borme, M. Sinou, K. Heggarty, and J. B. Nieder, “Multi-beam two-photon polymerization for fast large area 3D periodic structure fabrication for bioapplications,” Sci. Rep., vol. 10, no. 1, p. 8740, 2020.